Glove products

How Glove Manufacturers Are Shaping the Future of Latex-Free Gloves in 2025

Top glove makers are changing to latex-free disposable gloves. They do this because more people want these gloves. Industry rules are also changing. New ideas, machines, and caring for the planet have changed the market. The latex-free gloves market was worth USD 6.5 billion in 2024. It may reach USD 10.2 billion by 2033. Companies like Hartalega Holdings Berhad and INTCO Medical lead in new technology. They also have a big effect on the market. Their work helps many industries around the world. These include healthcare and food processing. They give safer and greener hand protection.

Industry Overview

Latex-Free Glove Trends

Latex-free gloves are now very important in many jobs. People in healthcare, food work, and labs use them a lot. These gloves help stop allergic reactions. The market for latex-free gloves keeps getting bigger. Many things make this happen:

• More people know about health and safety. They want cleaner and safer places.

• There is more money going into healthcare and new medical tools.

• Big health problems like COVID-19 made more people need disposable gloves.

• New rules say workers need better protection and must avoid allergies.

Manufacturers work hard to make better gloves. They use materials like nitrile and vinyl. These give good protection and feel comfortable. Some new gloves can break down in nature. Some smart gloves can check things in real time. Factories use machines to make more gloves for less money. Companies also care more about the planet. They use green materials and better ways to make gloves.

The market splits by type, thickness, use, and who uses them. Hospitals and clinics need gloves for exams and surgery. Food and factory jobs need thicker and stronger gloves. North America sells the most gloves. Asia-Pacific is growing the fastest because of new factories.

• Note: The latex-free glove market was about USD 2.6 billion in 2024. It may grow by 6.8% each year until 2031.

Market Leaders

Some companies are the top in latex-free gloves. They set the bar for quality and new ideas. They also have strong supply chains. The table shows some of the main companies and where they are:

|

Region/Aspect |

Market Leaders / Key Players |

|---|---|

|

Southeast Asia (Malaysia) |

Hartalega Holdings Berhad, Kossan Rubber Industries Bhd, Top Glove Corporation Bhd, Supermax Corporation Berhad |

|

Global Key Players |

Ansell Ltd., Kimberly-Clark Company, Atlantic Safety Products Inc., Supermax Corporation Berhad, INTCO Medical |

These companies spend money to learn and make new gloves. They bring out new products and sell them in more places. Hartalega and Top Glove use smart machines and care about the environment. In the U.S., Medline and Kimberly-Clark make new latex-free gloves for more people. What these companies do helps protect hands all over the world.

Hartalega Holdings Berhad

Innovation

Hartalega Holdings Berhad is a leader in making gloves. The company has changed the glove industry with new ideas and technology. Over time, Hartalega Holdings Berhad made big steps in latex-free gloves.

• The company made ultra-thin nitrile gloves first. These gloves are more comfortable and last longer. People use them in hospitals, food jobs, and factories.

• In June 2024, Hartalega Holdings Berhad made a new ultra-thin surgical glove. This glove helps doctors and nurses move their hands better.

• The research team keeps looking for new glove materials and designs. They want gloves to be safe, comfy, and work well.

Hartalega Holdings Berhad sends gloves to more than 50 countries. Hospitals, clinics, and factories use these gloves everywhere. The company’s new ideas help more people use latex-free gloves.

Automation

Hartalega Holdings Berhad uses smart machines to make gloves better. The company spends money on machines and artificial intelligence. This helps them make gloves faster and of good quality.

• In February 2025, Hartalega Holdings Berhad started using AI to check gloves. These systems look for problems in each glove.

• Machines help make more gloves with fewer mistakes. This saves money and keeps the gloves good.

• The company’s factories in Kuala Lumpur use new technology. Workers and machines work together to make millions of gloves every day.

Automation helps Hartalega Holdings Berhad stay ahead. The company can make more gloves when people need them.

ESG Initiatives

Hartalega Holdings Berhad cares about the planet and its workers. The company leads in environmental, social, and governance actions.

• Hartalega Holdings Berhad uses green materials for its gloves. The company tries to make less waste and save energy.

• The company treats workers fairly and keeps them safe. Training helps workers learn and stay safe at work.

• Hartalega Holdings Berhad shares its ESG goals and progress. This helps customers and partners trust the company.

A strong ESG plan helps Hartalega Holdings Berhad do well in a changing world. The company’s care for the planet and people makes it special.

Hartalega Holdings Berhad has 8-12% of the surgical glove market. Its money and global sales make it a top latex-free glove company.

INTCO Medical

Product Range

INTCO Medical is known for having many different products. The company makes many latex-free disposable gloves. These include nitrile, vinyl, Synmax vinyl, latex, and polyethylene gloves. Many jobs use these gloves, like healthcare, food work, labs, farming, and factories. INTCO Medical also makes rehab equipment, therapy tools, and cleaning supplies for homes.

The table below shows INTCO Medical’s many products and how well they do:

|

Product Category |

Examples of Products |

Market Success Indicators |

|---|---|---|

|

Medical Consumables |

Latex-free disposable gloves (nitrile, PVC) |

Revenue grew 37.65% to ¥9.523 billion; 56 billion nitrile gloves and 31 billion PVC gloves were made each year; sold in over 120 countries |

|

Rehabilitation Equipment |

E-LITE electric wheelchair, CAREFLEX nursing bed |

More rehab products with smart and comfy designs |

|

Physiotherapy & Household |

Physiotherapy products, household cleaning |

Many products for medical, work, and home use |

|

Innovation & R&D |

Biodegradable nitrile gloves, Dust-free gloves, syntex™ synthetic latex gloves |

¥398 million spent on R&D; 55 new products made; 43 new patents filed |

|

Manufacturing Capacity |

7 production bases in China and Vietnam |

All factories will be working in 2024; the biggest maker of latex-free gloves |

|

Global Marketing & Presence |

Multi-channel strategy including trade shows, e-commerce, and digital marketing |

Went to 31+ world events; on TikTok, Facebook, Tmall, JD.com; 3 B2B websites |

|

Awards & Recognition |

Various provincial and national awards |

Won many awards like Anhui Province Outstanding Private Enterprise, ESG Golden Bull Award |

INTCO Medical makes gloves that protect from chemicals, viruses, and germs. Their gloves are thin but still strong and comfy. The company uses less water and energy and recycles materials. This shows they care about the planet. Factories in China and Southeast Asia help make many products. This lets them get materials easily and make lots of gloves.

Industry Applications

INTCO Medical’s products help many jobs. In healthcare, their gloves keep doctors and patients safe during exams and surgery. Food companies use these gloves to keep food clean. Labs use them to stay safe from chemicals.

The company is also big in rehab equipment. They make wheelchairs, scooters, and therapy tools. Over 10,000 clients in more than 120 countries use these products. These places include America, Europe, Asia, Africa, and Oceania. Each year, they make 1,000,000 manual wheelchairs and 100,000 electric wheelchairs. More people want smart wheelchairs and therapy tools. This shows INTCO Medical likes new ideas and cares about health.

INTCO Medical’s gloves and tools also help in farming, beauty, tattoo, and cleaning jobs. Their products stop germs from spreading, protect from strong chemicals, and keep users comfy.

INTCO Medical’s worldwide supply chain makes sure products arrive on time. The company uses robots and smart machines to keep quality high and meet many needs.

Certifications

INTCO Medical has many certificates that show its products are safe and good. The company follows rules like ISO9001, FDA 510K, CE, ASTM, and TUV. These prove INTCO Medical’s products are high quality and safe to use.

The company spends a lot on research and new ideas. They put ¥398 million into R&D and have 55 new products being made. INTCO Medical filed 43 new patents, showing they like to invent. They check their products many times in labs to make sure they last and work well.

INTCO Medical helps partners make their glove brands. They have flexible factories and can make special orders. Fast shipping and good customer service make INTCO Medical a trusted supplier.

INTCO Medical wins awards for being green and following ESG rules. They got the EcoVadis “COMMITTED” badge and the ESG Golden Bull Award. These awards show the company grows in a good and fair way.

Challenges

Overcapacity

Glove makers have big problems with making too many gloves. Many companies built more factories faster. They thought people would keep buying lots of gloves. For example, Top Glove made 3.2 billion gloves in 2001. By 2019, they could make 64 billion gloves each year. Now, there are more glove factories than needed. Some machines sit unused and waste money. The condom industry has the same problem. They use similar materials and have too many products. They also have trouble getting enough money. New tariffs in the U.S. make it more expensive to make gloves. Companies must think about where to build their factories. The capacity utilisation rate shows how much a factory is really used. If companies build too much before people buy more, machines sit still. This wastes money and makes factories less efficient. To fix this, companies use ERP and MES systems. These tools help plan better and find slow spots in the process.

Cost Volatility

Glove makers worry about costs going up and down. Many things make prices change a lot. Raw material prices go up and down often. This makes it hard to plan how much money to spend. Shipping costs can rise very fast. For example, sending a big container from China to the U.S. West Coast went up 61% in six weeks. Labour, storage, and moving goods cost more when prices rise. Problems in the supply chain also make costs higher. High energy prices and how fast the economy grows change glove prices too. Too many gloves were bought during the pandemic. Now, extra gloves make prices lower. Companies must watch these changes to keep selling gloves.

Regulatory Risks

Rules and laws affect how glove companies work. Safety rules from OSHA and other groups say gloves must protect workers. In the U.S., hand injuries are 23% of all work injuries. Many happen because people do not wear the right gloves. The FDA and USDA have strict rules for gloves used with food. These rules cover how clean gloves are and what chemicals can move into food. Companies must pass hard tests to get certificates. Studies show gloves can spread germs if not made or checked correctly. This means companies need strong quality checks and must follow new rules.

Future Trends

Growth Opportunities

The latex-free glove industry is about to grow a lot. Some places, like Illinois, now ban latex gloves in hospitals and food jobs. This means more people want nitrile, vinyl, and synthetic gloves. The U.S. Customs and Border Protection checks if gloves are made fairly. This helps people trust the gloves and lets companies sell in new places. Canada is building its nitrile glove factories. This helps them buy fewer gloves from other countries and grow their own business. These actions show that governments want the industry to get bigger.

New technology is also important for the future. Companies make gloves that do not cause allergies and can break down naturally. These gloves help doctors, nurses, and people who care about the Earth. More money goes into healthcare, and rules for safety are getting tougher. People everywhere want to stay clean and safe, so the market keeps growing.

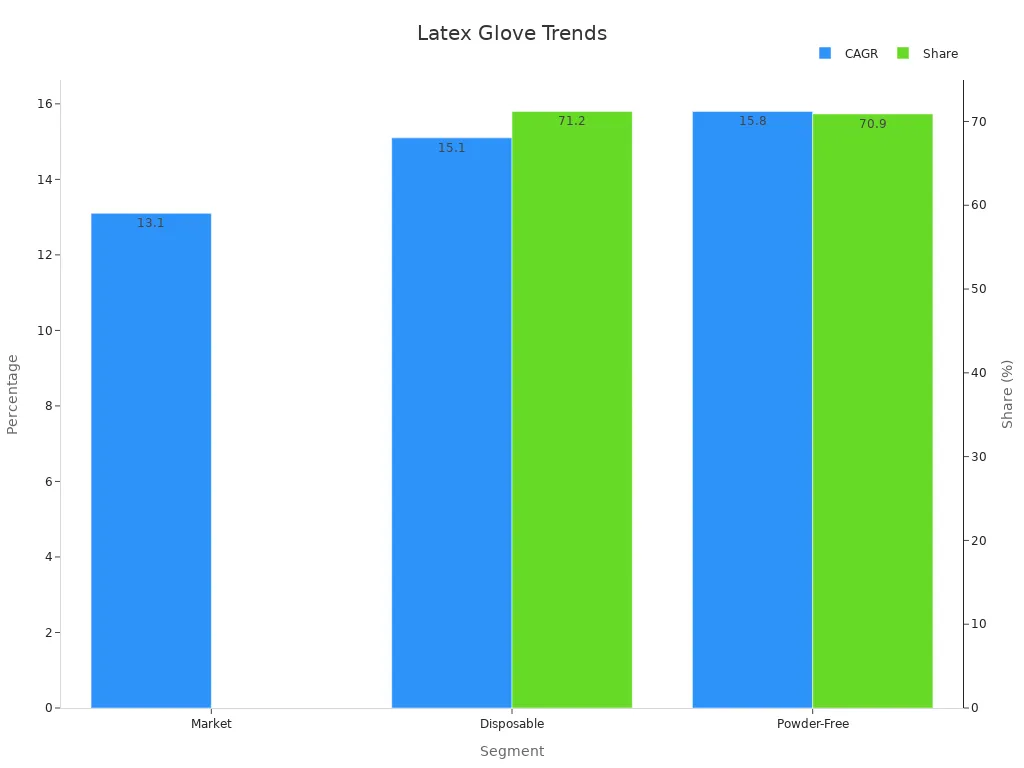

|

Aspect |

Details |

|---|---|

|

Market CAGR (2025-2032) |

13.1% |

|

Key Growth Drivers |

Healthcare, pharmaceuticals, automotive, chemicals, oil & gas |

|

Disposable Segment Share |

71.2% of sales; CAGR of 15.1% |

|

Powder-Free Segment Share |

70.9% of sales; CAGR of 15.8% |

|

Regional Growth |

Fastest in Southeast Asia and developing nations |

Customer Demands

People want gloves that keep them safe and fit well. Many buyers ask for powder-free and low-protein gloves. This helps stop allergies. Hospitals and clinics need gloves that pass hard safety tests. Food companies want gloves that keep food clean and safe. Factories want gloves that last long and protect from chemicals.

People also want to help the planet. They pick gloves made with less water, less energy, and recycled stuff. Factories use machines and AI to make more gloves quickly. These changes help companies make enough gloves and keep them good.

Note: The chart below shows powder-free and disposable gloves are the top sellers and grow the fastest.

Investment Outlook

Investors think the glove market will do very well. The global industrial gloves market could go from USD 11.38 billion in 2025 to USD 25.85 billion by 2033. North America is first because of strong safety rules and a lot of need in hospitals and factories. Companies spend money on machines, green materials, and new glove types to keep up.

The disposable latex gloves market might reach USD 10.5 billion by 2033. The market keeps growing as more countries want better health and make their own gloves. Big brands work on new ideas, open in more places, and use eco-friendly tech. These things show that the future for latex-free gloves is bright all over the world.

Hartalega Holdings Berhad and INTCO Medical are top in latex-free gloves. They use new ideas, smart machines, and care about the planet. Their plans help them do well when things change. Using green materials and digital supply chains is important. Making special products also helps companies stand out. People in the industry should spend money on research and new ideas. They should buy from different suppliers and watch for new rules. Every job can be done better by using these smart ways.