A Complete Guide to Nitrile Gloves for Professionals

Professionals often have to pick between latex and nitrile gloves. Nitrile gloves are made from special synthetic rubber. They give strong protection and feel comfortable in tough places. Many professionals choose them because they do not tear easily. It is easy to see if they get a hole. They also protect well against chemicals and germs.

• They help stop allergic reactions that latex gloves can cause.

• They last a long time and have a good grip for careful work. This helps even during long tasks.

Now, people care more about how gloves affect the environment. They also look for gloves with good certifications. Using facts helps professionals pick safe gloves, work well and are better for the planet.

Nitrile Gloves Overview

What Are Nitrile Gloves

Professionals often look at latex and nitrile gloves to protect their hands. Nitrile gloves are made from a man-made rubber called nitrile butadiene. This material does not have natural latex proteins, so it helps stop allergies. Nitrile gloves are made to fit the hand closely. They feel comfortable and let you move your fingers easily for a long time. These gloves come in many thicknesses and colours. People use them in healthcare, labs, food work, and factories.

Nitrile gloves are strong and do not tear or get holes easily. They protect hands from many chemicals like oils, solvents, and other dangerous substances. Many workers pick nitrile gloves when they need safety and to move their hands well. These gloves do not have powder, so they help keep things clean. This is important in hospitals and when making food.

Tip: Nitrile gloves do not have latex, so they are safe for people with latex allergies.

Key Properties

Nitrile gloves have several beneficial features that distinguish them from latex and vinyl gloves. The table below shows the main features and how they compare to other gloves:

|

Property |

Nitrile Gloves Characteristics |

Distinction from Other Disposable Gloves |

|---|---|---|

|

Chemical Resistance |

Stands up to oils, solvents, gasoline, acids, cleaning liquids, pesticides, and fuels |

Better at stopping chemicals than latex and vinyl gloves |

|

Allergenicity |

No latex, so they do not cause latex allergies |

Latex gloves can cause some peopleto have allergic reactions |

|

Puncture & Tear Resistance |

3-5 times stronger against holes than latex gloves of the same thickness |

Last longer and keep hands safer |

|

Flexibility & Tactile Sensitivity |

Flexible and let you feel things well, almost as good as latex but better than before |

Better than vinyl, almost as good as latex |

|

Thickness Options |

Can be thin (3-4 mil) or thick (7-8+ mil) for different jobs |

You can pick the right glove for your job |

|

Surface Texture |

Can be smooth, have textured fingertips, or be fully textured for better grip |

Different textures help with different jobs |

|

Comfort & Fit |

Fits the hand better over time and helps stop tired hands |

More comfy than vinyl, about the same as latex |

|

Limitations |

Can break down with some chemicals like acetone |

Latex and vinyl break down with other chemicals |

• Nitrile gloves are very strong and do not tear easily.

• They keep their hands safe from many chemicals like oils and solvents.

• The gloves fit well and help hands not get tired after long use.

• You can get them in different thicknesses for more or less protection.

• Nitrile gloves do not cause latex allergies.

Nitrile gloves are now the top pick for workers who need tough and safe hand protection. They last a long time and keep hands safe from chemicals, so they are great for hard jobs and careful work.

Composition and Manufacturing

Materials Used

When people look at latex vs nitrile gloves, they check what each is made of. Makers use acrylonitrile butadiene rubber (NBR) as the main part for these gloves. NBR has acrylonitrile, which makes the gloves tougher and better against oils. This also helps the gloves stop holes and scratches better than natural rubber. To make the gloves stronger and cheaper, makers add things like calcium carbonate or clay powder. They also put in special chemicals to help the gloves stay soft and bendy. These things help the gloves feel nice and fit well. The finished gloves keep hands safe from chemicals and germs. This makes them good for doctors and factory workers.

Manufacturing Steps

Making these gloves takes many steps:

1、Workers mix NBR with other things to make a smooth base.

2、They clean the glove moulds so nothing dirty gets in.

3、The moulds are dried in hot ovens to get rid of water.

4、A sticky liquid goes on the molds to help the glove form.

5、The moulds are dipped into the NBR mix to make the glove shape.

6、The gloves are washed to take out bad stuff and extra chemicals.

7、The gloves are heated to make them strong and stretchy.

8、Workers wash and pull the gloves off the moulds.

9、Each glove is checked and packed to make sure it is safe.

Note: Every step helps make sure the gloves are safe and work well.

Quality Assurance

Makers follow strict rules to make sure the gloves are safe and work right. They use tests like ASTM D5151 to look for leaks or holes. Other rules, like ISO 11193-1 and EN 455, check how strong and thick the gloves are and if they stop germs. Certifications like ISO 9001:2015 and FDA 510(k) show the company makes good gloves and follows world rules. These steps help workers trust that the gloves will work well in hard jobs.

Glove Comparison

Nitrile Gloves vs Latex

Professionals often talk about which glove is better. They compare latex and nitrile gloves for tough jobs. Both types keep out dirt and germs, but they are different. Latex gloves are made from natural rubber. Nitrile gloves use a man-made rubber. This makes them different in how strong, bendy, and safe they are for people with allergies.

Latex gloves are very bendy and let you feel things well. Surgeons and dentists like them for their careful work. But latex gloves can rip easily. They do not protect well from strong chemicals. Some people get allergies from latex gloves because of the proteins inside.

Nitrile gloves are stronger and do not rip as fast. They keep their hands safe from oils, acids, and other chemicals. This makes them good for labs and factories. New nitrile gloves are now softer and let you feel things better. They do not have latex proteins, so they are safer for people with allergies.

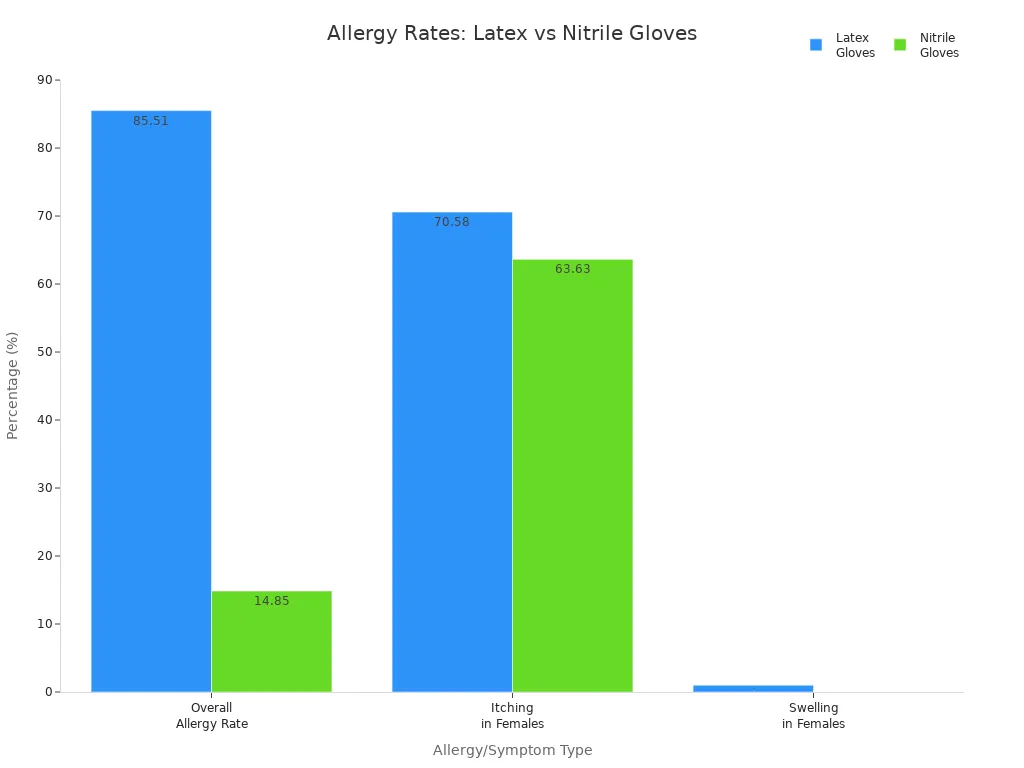

A study with 356 people showed that most got allergies from latex gloves. Only a few had problems with nitrile gloves. People with latex gloves had more itching, swelling, and trouble breathing. The chart below shows how often people had allergies and symptoms:

Hospitals now use nitrile gloves more to keep workers and patients safe from allergies. These gloves last longer and protect better from chemicals. That is why many workers trust them more.

Tip: If you worry about chemicals or allergies, nitrile gloves are safer and last longer than latex gloves.

Nitrile vs Vinyl

People also look at nitrile gloves and vinyl gloves for different jobs. Vinyl gloves are made from PVC and cost less. They fit loosely and do not stretch much. This makes them easy to put on, but not comfortable for long use.

Nitrile gloves protect better from chemicals and sharp things. They fit tightly to the hand, which helps with careful work. Doctors, lab workers, and factory workers like nitrile gloves for these reasons. Vinyl gloves are cheaper but do not protect or fit as well. They are best for quick, easy jobs like making food or cleaning.

• Nitrile gloves are stronger, fit better, and protect from chemicals more than vinyl gloves.

• Vinyl gloves are cheaper but do not stretch or protect as well.

• Workers pick nitrile gloves for jobs that need careful handwork and long wear.

• Vinyl gloves are good for short, easy jobs where saving money matters most.

Doctors and factory workers now use nitrile gloves more because they are safer, more comfortable, and work better.

Types and Features

People often look at latex and nitrile gloves to pick the best one for work. Knowing about the types and features of nitrile gloves helps people choose what they need.

Grades and Uses

Nitrile gloves have two main grades. Each grade is made for different jobs. The table below shows how they are different:

|

Grade |

Description |

Typical Industries/Users |

|---|---|---|

|

Medical Grade |

Used by healthcare workers; designed to protect against bodily fluid contamination and infectious diseases; FDA-regulated in the US. |

Healthcare (hospitals, clinics) |

|

Industrial Grade |

Designed for protection against hazardous chemicals and sharp objects; offers high puncture and chemical resistance; thickness varies (6-8 mm). |

Automotive, janitorial, food services, waste management |

Medical-grade gloves keep doctors and nurses safe from germs and fluids. Industrial-grade gloves protect workers from chemicals and sharp things. Both grades must follow strict rules to keep people safe.

Powdered and Powder-Free

Nitrile gloves can be powdered or powder-free. Each kind has its good points:

• Powdered gloves have cornstarch. This makes them easy to put on and take off. They help stop the gloves from sticking or tearing.

• Powdered gloves can leave powder on hands, clothes, or tables. This can make things dirty or unsafe.

• Powder-free gloves do not leave any powder behind. They help keep places clean and lower the chance of spreading germs.

• Powder-free gloves are better for people with allergies. They are safer for careful work.

• Washing hands is still important, no matter which glove you use.

A study showed that using powder-free gloves helped healthcare workers wash their hands more. This made it safer and lowered the risk of infection.

Thickness and Texture

How thick and textured a glove is changes how it works. Thicker gloves, like 6-8 mil, protect well from chemicals and sharp things. These gloves are good for hard jobs but can be less bendy. Thinner gloves, about 3-4 mil, let you move your fingers better. They are good for jobs that need careful handwork.

Texture is important too. Gloves with tiny bumps or diamond shapes grip better, even when wet or oily. Some gloves have a special inside layer. This makes them easy to wear for a long time and keeps hands cool. Gloves that stretch and fit well help stop hands from getting tired.

Picking the right thickness and texture helps keep hands safe and comfy for every job.

Environmental Impact

When people pick between latex and nitrile gloves, they also think about the environment. More gloves are used in hospitals, food places, and factories now. This makes people worry about trash and how to protect nature. Knowing how nitrile gloves affect the earth helps groups make good choices.

Biodegradability

Old nitrile gloves are made from man-made stuff like acrylonitrile and butadiene. These gloves do not break down fast. They can stay in landfills for 100 to 200 years. Newer nitrile gloves can break down in three to five years if composted the right way. First, the outside wears away. Then, tiny germs eat the rest. But you must throw them away the right way. If not, even new gloves can last a long time. Scientists do not have clear answers yet about which glove breaks down fastest.

Recycling Options

Many jobs now try to recycle nitrile gloves to make less trash. There are some easy ways to help recycling work:

• Check how many gloves are used to plan recycling.

• Work with companies that recycle nitrile gloves.

• Teach workers how to throw away and recycle gloves.

• Put bins with clear signs where people can reach them.

• Set up times to collect and send gloves to be recycled.

• Make sure gloves are clean and safe before recycling.

• Give rewards to get more people to join in.

Some programs, like VWR Glove Recycling and Kimberly-Clark Glove Recycling, take clean nitrile gloves. They use special places to turn old gloves into energy. This helps cut down on trash and saves money.

Sustainable Practices

INTCO Medical is a leader in making gloves that are better for the earth. They spend money to find new ways to make eco-friendly gloves. They make gloves that break down and weigh less. INTCO Medical has awards for being good to the planet and people. They use smart machines to make less waste and work faster. Other companies are doing the same because of rules and people wanting greener products.

Picking nitrile gloves from green companies helps keep workers safe and protects the earth.

Sustainability Certifications

When people pick between latex and nitrile gloves, they look at safety and how well the gloves work. They also check if the gloves have special green certifications. These certifications show that the gloves are good for the earth and people. INTCO Medical is a top company for getting Life Cycle Assessment (LCA) and carbon footprint certifications. These awards help workers pick gloves that are better for the planet.

LCA and Carbon Footprint

LCA means Life Cycle Assessment. It checks how gloves affect the Earth from start to finish. The carbon footprint tells us how much pollution each glove makes. Latex and nitrile gloves have different footprints because they use different materials and ways to make them. Companies like INTCO Medical use LCA facts to make gloves that are better for the earth.

Importance in Healthcare

Green certifications are very important in hospitals and clinics. These places use the certifications to make sure their glove makers care about the earth and people. Here are some good things about these certifications:

• Certifications like ISO 14001 and ISO 26000 check if glove makers do the right thing.

• They help hospitals follow rules like the EU’s Corporate Sustainability Reporting Directive and NHS Net Zero Strategy.

• They help hospitals run better and avoid trouble with the law.

• They make glove makers show where their gloves come from and how they are made.

Hospitals now ask glove makers to show green reports and certifications. This helps hospitals buy gloves that are safer for people and the planet. It also helps them reach their climate and health goals.

Professional Guidance

When professionals look at latex vs nitrile gloves, they need to think about many things. Safety and how well the gloves work are very important. The best glove depends on the job and where it is used. It also depends on what dangers are there. Picking the right glove means knowing the rules and paying close attention.

Selecting Nitrile Gloves

Professionals should use clear steps to pick gloves for each job:

• Intended Use: Decide if the gloves are for surgery, exams, or lab work.

• Compliance with Standards: Pick gloves that meet EN 374 and EN 455 rules.

• Glove Thickness: Thin gloves (3-5 mil) are good for careful hand work. Thick gloves (6-8 mil) give more protection.

• Fit and Sizing: Use a size chart to find the best fit.

• Glove Length: Longer gloves cover more skin for splash or soaking jobs.

• Grip and Texture: Gloves with textured fingers or palms help you hold things better.

• Powder-Free vs. Powdered: Powder-free gloves help stop allergies and keep things clean.

• Sterile vs. Non-Sterile: Sterile gloves are for surgeries. Non-sterile gloves are for regular jobs.

• Environmental Impact: Think about gloves that are better for the earth and have less waste.

• Food Safety Certification: Make sure gloves are safe for food work.

Note: Not every glove stops all chemicals. Always check a chemical chart before using gloves.

Addressing Misconceptions

Some people believe things about gloves that are not true:

• Some think all gloves protect and feel the same. But gloves are different in how strong, bendy, and safe they are.

• Some think nitrile gloves never cause allergies. They are safer for most people, but a few can still react.

• Some think gloves last forever. But gloves break down faster in heat and sunlight.

• Taking off gloves the right way is very important. This helps stop germs from spreading.

Tip: Powder-free gloves help lower allergy risks and keep places safer.

Staying Informed

Professionals should always learn new things about gloves. They can:

• Go to classes and workshops.

• Read news from trusted groups.

• Check product labels and certifications.

• Look at chemical charts for each job.

• Learning more helps professionals pick the best gloves and stay safe at work.

When workers look at latex and nitrile gloves, they notice some big differences. Nitrile gloves are safer and work better for many jobs. They protect hands from strong chemicals and sharp things. People with latex allergies can use them without worry. These gloves fit tightly and have a grip that helps with careful work.

It is important to pick gloves that are good for the earth. Workers should check how thick the gloves are and if they are powder-free. Picking the right size also matters. Learning about gloves by using charts and training helps everyone make smart choices and stay safe.

FAQ

What is the main difference between latex vs nitrile gloves?

People often ask about latex and nitrile gloves. Latex gloves are made from natural rubber. Nitrile gloves are made from synthetic rubber. Nitrile gloves protect better from chemicals. They do not cause latex allergies. Many workers pick nitrile gloves for safety and comfort.

Can nitrile gloves protect against all chemicals?

Nitrile gloves keep out many chemicals, like oils and solvents. But some strong chemicals, such as acetone, can damage them. Always look at a chemical chart before using gloves.

Are nitrile gloves safe for people with sensitive skin?

Nitrile gloves do not have latex proteins. This helps stop allergic reactions. Some people may react to extra chemicals in the gloves. Most people with sensitive skin can use nitrile gloves safely.

How should professionals dispose of used nitrile gloves?

Workers should throw used nitrile gloves in the right trash bins. Some places have recycling for gloves. Always follow local rules to keep people and nature safe.

How do I choose the right size and thickness for nitrile gloves?

Measure your hand to find the right size glove. Thin gloves (3-4 mil) are good for jobs needing touch. Thick gloves (6-8 mil) protect better for hard work.